RUBBER & TYRE INDUSTRY AUTOMATION

At Invent Controls Private Limited , we understand the unique challenges faced by rubber manufacturers. With our automation solutions, we aim to enhance productivity, quality control, and operational efficiency while reducing costs and environmental impact.

Our experienced team of professionals works closely with clients to develop customized automation solutions that align with their manufacturing processes and goals. We offer comprehensive support, from system design and installation to training and ongoing maintenance.

Experience the transformative power of automation in the rubber industry. Contact invent controls private limited today to explore our advanced automation solutions and discover how we can help you achieve new levels of efficiency and success in rubber manufacturing.

Invent Automation Benefits

Mixing and Compound Automation

Our automation solutions streamline the mixing and compounding processes in rubber manufacturing. We offer advanced control systems that precisely monitor and adjust the parameters such as ingredient ratios, mixing time, temperature, and pressure. With our automation solutions, rubber manufacturers can achieve consistent batch quality, reduce material waste, and increase production throughput.

Material Handling and Conveying Automation

Our automation solutions for material handling and conveying optimize the movement of raw materials, intermediates, and finished products throughout the rubber manufacturing facility. We provide robotic systems and advanced conveyor solutions that automate the loading and unloading of materials, ensure accurate material flow, and enhance overall productivity.

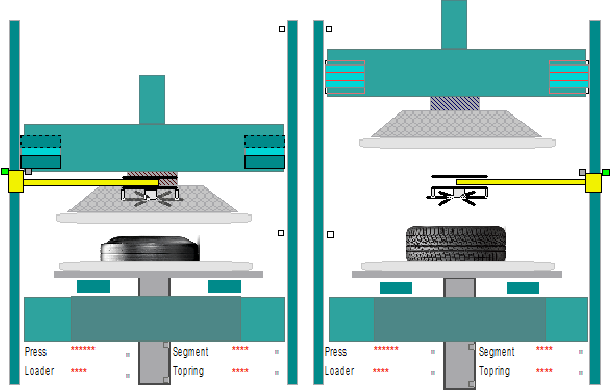

Press Automation

Our automation solutions for rubber pressing processes significantly improve efficiency and precision. We offer advanced press control systems that monitor and optimize parameters such as temperature, pressure, and cycle time. By automating the pressing process, rubber manufacturers can achieve uniform product quality, reduce cycle times, and enhance throughput.

Curing and Vulcanization Automation

Our automation solutions for curing and vulcanization processes enable precise control and optimization of temperature, pressure, and curing time. We provide advanced control systems that ensure consistent product quality, reduce curing defects, and increase production efficiency. Our solutions also include real-time monitoring and automated feedback mechanisms to optimize curing parameters.

Quality Inspection and Testing Automation

We offer automation solutions for quality inspection and testing in the rubber industry. Our vision inspection systems use high-resolution cameras and advanced image analysis algorithms to detect defects, such as surface irregularities, air bubbles, and foreign particles. With automated quality inspection, rubber manufacturers can ensure superior product quality and reduce the risk of defective products reaching the market.

Data Analytics and Reporting

Our automation solutions encompass comprehensive data analytics and reporting systems. By collecting and analyzing data from various sensors and equipment, our systems provide valuable insights into production processes, quality metrics, and resource utilization. Real-time data visualization and reporting enable data-driven decision-making, process optimization, and continuous improvement.

Integration and Connectivity

Our automation solutions seamlessly integrate with existing systems and equipment in the rubber manufacturing facility. We provide connectivity solutions that enable interoperability between automation systems, legacy infrastructure, and other manufacturing technologies. This ensures a smooth transition to automation while maximizing the value of existing investments.